Forging is a manufacturing process of flattening, hammering or extruding metals with great pressure to form high-strength metal parts. In general, except in special cases, metals before forging should be preheated to reach anticipated temperature. It is noted that forging and casting are different manufacturing process and forgings don’t require pouring after melting of metals like castings.

Compared with metal parts formed by other manufacturing processes, forgings have higher strength. That’s why people choose forgings when relatively high reliability and security are required. However, under normal circumstances, forgings seem to be rarely seen as assembling parts for applying in airplanes, automobiles, tractors, ships, oil drilling equipment, engines, guided missiles and some other main equipment.

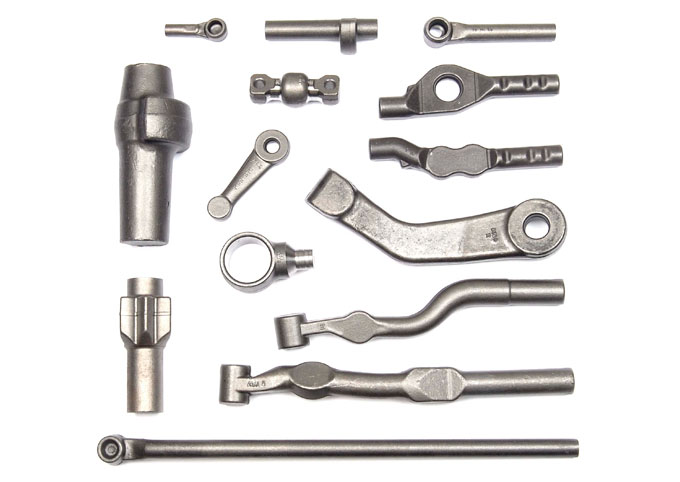

Forgings vary in dimensions, shapes and complexity, from hammers and wrenches to assembling parts with precise tolerance mounted in space shuttles like Boeing 747 and NASA spacecrafts. In reality, 18,000 assembling parts mounted in Boeing 747 are forgings. The major applications of forgings include aerospace industry, national defense construction, automobile industry, agriculture, building industry, mining industry, material handling industry, general industrial equipment, etc.

Nearly all metals can be forged. Commonly used metals mainly include carbon steels, alloys, stainless steels, tool steels, aluminum, titanium, brass, copper as well as high temperature alloys containing cobalt, nickel and molybdenum. Every metal has its own strength and weight. Based on different features, metals are used as special parts specified by customers. In spite of diversity of drive systems and types, any device or method below can be used for manufacturing forgings.

(1) Forging hammer: driving force can reach up to 50,000 pounds. Deformation of metals can be achieved by beating metals with controllable impact force.

(2) Press machine: driving force can reach up to 50,000 tons. Vertical deformation of metals can be achieved by extruding metals with controllable pressure.

(3) Upsetting: the basic forging process used for horizontal upsetting. Roll forgings are ring parts formed by extruding circular hollow metal parts through roller rolling under relative pressure and not requiring welding process.

To some extent, the above-mentioned devices and method can help designers to produce forgings with some basic advantages. The forging with directional strength improves microstructure of metals and leads to optimal grain flowing deformation so as to achieve anticipated directional properties, such as tensile strength, ductility, impact resistance, crack resistance and fatigue resistance. The integrity of forging structure is not affected by internal porosity and incompact state. During forging process, metal materials are relatively homogeneous, which makes forgings have uniform mechanical properties and meet anticipated preheating effect. Through appropriate deformation and grain flowing deformation and high homogeneity of materials, dynamic mechanical properties can greatly improve impact resistance, crack and fatigue resistance properties of forgings. Because of the favorable properties, forgings are suitably applied in security and some other relevant fields.