Nowadays, global automobile manufacturers are facing with severe challenge because of global energy and environment situation.

Energy conservation has already become an important of future development strategy for every automobile manufacturer. As one of important measures, light weight has attracted attentions from manufacturers. Meanwhile, strict emission regulation forces

OEMs to take action. In Europe, on July 11, 2012, European Commission announced that it had already made a new proposal for emission standard of new vehicles in EU. It regulated that upper limit of carbon dioxide of sold new-vehicles in EU would be 95g/km. And the goal would be upgraded as mandatory standard. To realize the goal of reducing carbon dioxide to 95g/km by 2020, 9 of 11 global main OEMs including common manufacturers and high-end manufacturers predict that total weight of every automobile is reduced by 100kg at least per year.

To realize light weight, every automobile takes measure. Hyundai uses amount of function on its current value chain to reduce weight. To maintain its constant leadership position, BMW is predicted that it will create new partnership to keep its investment on innovative materials. The variation of thickness on pillar made of ultrahigh-strength steel will reduce weight by 4kg. Bed plate and cylinder head of engine made of magnesium will reduce weight by 10kg at most. Steel transferring into thermoplastic plastics on bulkhead will reduce weight by almost 10kg. The whole objective of Volkswagen is to get a basic ecological reconstruction formula to accelerate and meet the requirements of carbon dioxide emission. Aluminum taking place of steel on nacelle cover will reduce by 7kg at most. Pillar, base plate, roof cross beam and side beam made of new steel will be reduced by 18kg at most. Ford will use innovation as a key of its future development strategy of light weight. Steel changing into carbon fiber reinforced plastics on bonnet will reduce 50% of weight at most. Considering cost and light weight effectiveness, OEMs will adopt at least three modularization lightweight components – evolution, innovation and revolution. All of them are defined by contents of raw materials, originated from requirements of carbon dioxide emission. These components are estimated to become differentiation competing models, promoting sales volume as brand innovation. On K-car and entry-level car market, application of high-strength steel and ultrahigh-strength steel should be expanded. Facing with market in developed countries, high-end products will use aluminum, magnesium and other materials instead of steel. On mature market such as the U.S. and Germany, luxury cars, electric vehicles, sports cars and other top vehicles having less cost pressure will largely use carbon fiber and other composites.

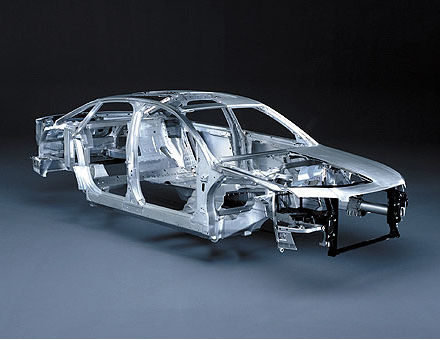

In general, for current body-in-white made of steel or aluminum, OEM will focus on body structure parts. On luxury cars, body panels (roof cover and trunk lid) largely use carbon fiber reinforced plastics since 2015, skipping the application of aluminum. When deploying lightweight solution, maintaining low cost and high productivity are vital for large-scale application.